Food industry

Dry lemon slices dried by microwave vacuum at low temperature

Microwave vacuum low-temperature drying equipment is developed to provide a new and efficient low-temperature drying process for the deep processing of food, pharmaceutical, biological, chemical, new materials and agricultural by-products. It can control the flower buds and

Corolla shall be dried at low temperature or dehydrated at low temperature to keep certain shape and fragrance.

Including rose bud, rose crown, rose petal, Damascus, bitter rose, chrysanthemum, honeysuckle, camellia, peach, osmanthus, peony, jasmine, lavender, Luoshen flower, marigold, lily

Low temperature drying of flower products.

At the same time, it can collect the cell fluid of roses, essential oil evaporated at low temperature and other by-products.

It can also dry and expand sliced products such as lemon and balsam pear at low temperature, including volatile, flammable and explosive products such as ethanol and methanol. It can also recover the evaporated substances during drying, which is safe, environmentally friendly and reduces environmental pollution.

Microwave vacuum low-temperature drying equipment is developed to provide a new and efficient low-temperature drying process for the deep processing of food, pharmaceutical, biological, chemical, new materials and agricultural by-products. For most fruits and vegetables

Carry out low-temperature dehydration and drying, including low-temperature drying of banana slices, jackfruit, figs, lotus seeds, red dates and red date slices, cashews, walnut kernels and walnuts with shells, ginkgo with shells, siraitia grosvenorii, chickpea, medlar fruit and other fruit products.

General use:

1. The initial water content of the material is below 80%.

2. The dryness is required to be within 1% - 20%.

3. The drying temperature is within 20-120 ℃.

4. The material is powder or granular, and there is no requirement on the appearance after drying.

5. It can meet the intermittent operation performance.

Common types are:

1. Drying temperature: 10-100 ℃.

2. High vacuum: ≥ -0.096Mpa.

3. Recovery of evaporation: more than 90% of the evaporated gas is effectively recovered.

4. Multi-purpose machine: can dry various materials.

5. Condensation temperature: - 20 ℃. It is comparable to the freeze-drying effect.

Other special purposes:

Microwave vacuum wall breaking:

Microwave vacuum low-temperature drying dehydration:

Microwave vacuum low-temperature sterilization:

Microwave vacuum carbonization:

Microwave vacuum removal of pesticide residues:

Microwave vacuum expansion:

Microwave vacuum desulfurization and deacidification

1. Low drying temperature - lower than 30 ℃,

2. Recoverable evaporation ---- Recoverable condensable matter above 0 ℃.

3. It can evaporate and separate the residues of organic pesticides and sulfides inside the material -- after reduction, it can reach PPM level.

4. The vacuum degree is high when the equipment is working -- above -0.096.

5. When drying roses, three products can be obtained at the same time - sulfur-free rose dry flower, super rose cell fluid and super rose essential oil.

6. Design service life > 12 years.

Equipment power supply: three-phase four-wire 380V ± 10% 60Hz ± 1%

Microwave output frequency: 2450 ± 50MHz

Input apparent power: ≤ 45KVA

Microwave output power: 30KW (power adjustable)

Dehydration and drying efficiency: 30-35kg/h

Equipment vacuum strength: ≤ 1000-500pa (digital vacuum meter)

Polypropylene material box: 600 * 150 * 150mm with 30

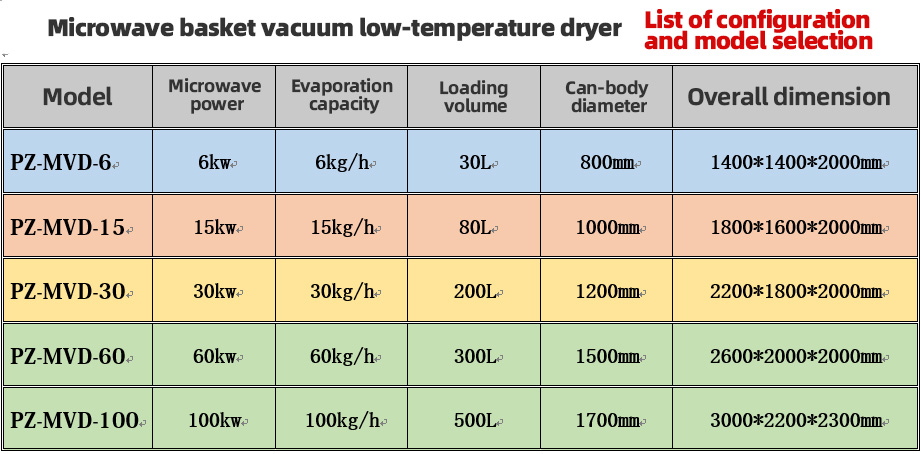

The overall size of the equipment is about: (length × wide × High) 2500 × two thousand × 2000mm